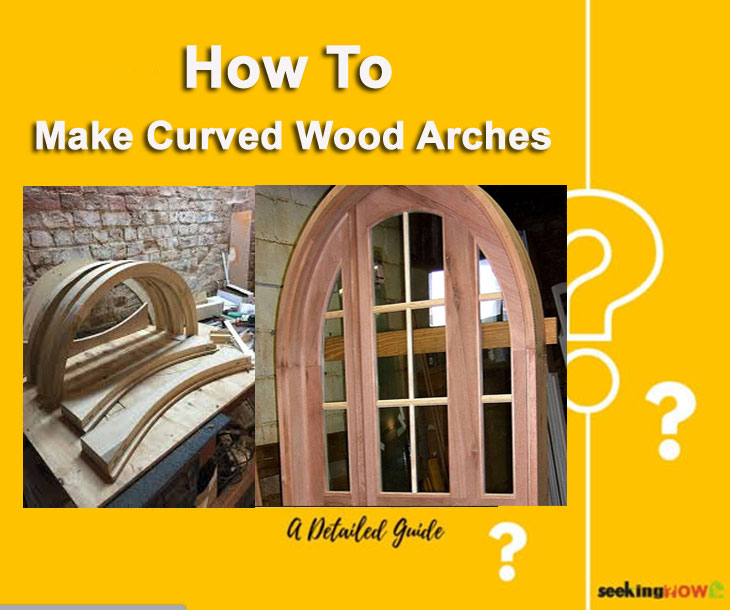

Crafting curved wood arches is both an art and a science. This classic design element has adorned homes and buildings for centuries, providing both aesthetic and structural advantages. Whether you’re looking to create a sophisticated entranceway, embellish a cabinet, or even frame a garden path, understanding how to make curved wood arches can be a valuable skill. This guide will help you navigate through the process, offering clear, step-by-step instructions on How To Make Curved Wood Arches and a list of required materials.

Required Materials for Making Curved Wood Arches:

- Quality hardwood or plywood (depending on the project and budget)

- Jigsaw or bandsaw

- Chisels

- Wood glue

- Clamps

- Sandpaper (various grits)

- Compass or flexible ruler for drawing curves

- Pencil or chalk

- Safety goggles and gloves

- Measuring tape or ruler

How To Make Curved Wood Arches

Curved wood arches are timelessly elegant and can enhance the beauty of various architectural elements, from windows to doors, and even furniture. But how exactly do you craft one? Let’s explore the process.

1. Preparing and Planning

Begin by deciding the size and shape of your arch. Measure the space where you intend to place it and sketch the desired curve on a piece of paper. This will act as your template.

2. Choosing the Right Wood

While hardwoods like oak or walnut are durable and beautiful, they can be challenging to curve. Plywood or laminated veneers might be easier for beginners as they bend more readily.

3. Drawing the Curve

Place your wood on a stable surface. Using a compass or a flexible ruler, draw the arch’s curve, ensuring it’s symmetrical and fits your initial sketch.

4. Cutting the Curve

Wearing safety goggles and gloves, cut along the marked curve using a jigsaw or bandsaw. Remember to move slowly to maintain precision.

5. Refining the Arch

There might be rough edges or imperfections after cutting. Using chisels and sandpaper, refine the curve until it’s smooth. Start with a coarse grit and gradually move to finer grits for the best finish.

6. Laminating (if required)

For deeper curves or added strength, you might want to laminate multiple thin layers of wood. Apply wood glue between each layer, press them together, and clamp until dry.

7. Fixing the Arch

Depending on where you’re placing the arch, you might need to secure it with screws or additional wood pieces. Always pre-drill holes to avoid splitting the wood.

8. Finishing Touches

Seal your arch with a wood finish to enhance its beauty and durability. Consider staining if you want to alter its color or match it with existing woodwork.

9. Safety First

Throughout the process, prioritize safety. Always wear protective gear, work in a well-ventilated area, and make sure your tools are sharp and well-maintained.

10. Maintenance

Wood expands and contracts with temperature and humidity. Check your arch periodically for any signs of stress or wear. A well-made arch, if maintained, can last for generations.

Conclusion:

Making a curved wood arch may seem daunting, but with the right tools, patience, and practice, it’s a project that offers immense satisfaction. Whether it’s a centerpiece for your home or a functional element in your garden, the charm of a handmade wooden arch is undeniable.

Understanding Curved Wood Arches

Wood arches can add a unique touch to architectural designs, bringing elegance and sophistication to any space. Curved wood arches, in particular, have the power to create visually stunning structures that stand out from the rest. Understanding the intricacies of curved wood arches is essential for anyone interested in incorporating them into their designs.

In this section, we will delve into the definition and types of curved wood arches, as well as explore examples of their applications. Let’s begin by defining what curved wood arches are and the different types available.

Definition And Types Of Curved Wood Arches:

- Curved wood arches are structural elements made from wood that follow a curved shape, creating an aesthetically pleasing and structurally sound effect.

- There are different types of curved wood arches, including the Roman arch, Gothic arch, and elliptical arch. Each type has its unique characteristics and uses in architectural designs.

- The Roman arch features a semi-circular shape, creating a timeless and classic look. It has been used in various architectural styles throughout history.

- The Gothic arch, on the other hand, is pointed at the top, giving it a more dramatic and intricate appearance. It is commonly associated with Gothic architecture and adds a sense of grandeur to any space.

- The elliptical arch has a more elongated shape, resembling a flattened oval. It offers a contemporary twist to traditional arch designs and works well in modern and minimalist aesthetics.

Now that we have a better understanding of curved wood arches and their types, let’s explore some examples of their applications in architectural design.

Examples Of Curved Wood Arch Applications:

- Curved wood arches can be found in historical buildings and landmarks, such as cathedrals, castles, and palaces, adding a touch of grandeur and architectural excellence.

- In modern architecture, curved wood arches are frequently used in the construction of bridges, both for their structural integrity and aesthetic appeal. The arches provide strength and support while creating a visually striking feature.

- They can also be incorporated into interior design, adding elegance to staircases, doorways, and room entrances. Curved wood arches can transform ordinary spaces into extraordinary ones, evoking a sense of beauty and sophistication.

- Curved wood arches are not limited to large-scale structures. They can be utilized in furniture design, creating unique and eye-catching pieces that become focal points in any space.

- Another application of curved wood arches is in landscaping and outdoor structures. From pergolas to garden arbors, these arches add a touch of elegance and create inviting spaces in outdoor settings.

Understanding the definition and types of curved wood arches gives us a solid foundation for appreciating their applications. Whether in historical buildings, modern architecture, interior design, furniture, or landscaping, curved wood arches have the power to transform spaces and captivate the eye.

In the following sections, we will dive deeper into the process of making curved wood arches and explore techniques and considerations for successful execution.

Tips For Successful Curved Wood Arch Construction

Making curved wood arches can be a challenging yet rewarding woodworking project. To ensure successful construction, it’s important to focus on accuracy and precision, measure and mark meticulously, use accurate cutting tools, and employ proper clamping and finishing techniques. In this section, we will delve into these key tips for achieving excellent results with curved wood arches.

Accuracy And Precision:

- Accurate measurements and precise calculations are the foundation of successful curved wood arch construction.

- Take the time to measure and mark your materials carefully to ensure a seamless fit and optimal structural integrity.

- Double-check your measurements and calculations before proceeding with cutting and assembly.

Importance Of Measuring And Marking:

- Measuring and marking are crucial steps in creating curved wood arches.

- Use a reliable measuring tool, such as a tape measure, to accurately determine the dimensions of your arch.

- Mark the points where the arch will start and end, as well as any critical reference points along the curve.

- Proper measurements and markings will guide you throughout the construction process.

Utilizing Accurate Cutting Tools:

- A high-quality cutting tool is essential for achieving clean and precise cuts on curved wood arches.

- Choose a tool that is specifically designed for curved cuts, such as a jigsaw or a bandsaw.

- Ensure that the blade is sharp and suitable for the material you are working with.

- Take your time when cutting and maintain a steady hand to achieve accurate results.

Clamping And Finishing:

- Proper clamping techniques play a vital role in ensuring the stability and durability of curved wood arches during assembly.

- Use clamps to hold the pieces securely in place while the glue dries or as you make adjustments.

- Position the clamps strategically to distribute pressure evenly and prevent warping or distortions.

- Prioritize safety and always follow the manufacturer’s instructions when working with clamping tools.

- When it comes to finishing, curved wood arches offer various options to enhance their appearance and protect the wood.

- Consider applying a high-quality wood finish, such as varnish or oil, to bring out the natural beauty of the wood.

- Sand any rough edges or imperfections before applying the finish for a smooth and polished look.

- Experiment with different finishing techniques to achieve the desired aesthetic effect.

By adhering to these tips for successful curved wood arch construction, you can create stunning architectural elements that add elegance and intrigue to your woodworking projects. Remember to prioritize accuracy, precision, and attention to detail throughout the process for the best results.

Now, let’s dive deeper into each tip to explore the intricacies of achieving curved wood arch mastery.

Troubleshooting Common Challenges In Curved Wood Arch Construction

Dealing With Wood Splitting Or Cracking

When it comes to constructing curved wood arches, one common challenge that many woodworkers face is the occurrence of wood splitting or cracking. This can be frustrating, but with the right steps, you can troubleshoot and minimize these issues. Here are some key points to keep in mind:

- Choose the right wood: Opt for high-quality, well-seasoned lumber that is less prone to splitting. Hardwoods like oak or maple are excellent choices.

- Pre-drill holes: Before fastening the wood together, it’s essential to pre-drill pilot holes. This helps prevent the wood from splitting when nails or screws are inserted.

- Use appropriate joinery techniques: Depending on the design of the arch, consider using techniques such as mortise and tenon or lamination to distribute forces evenly and reduce the risk of splitting.

- Avoid placing fasteners near the edges: Nails or screws placed too close to the edge of the wood are more likely to cause splits. Maintain a safe distance to minimize this risk.

- Allow for wood movement: Wood naturally expands and contracts due to changes in humidity. Ensure that the design accounts for this movement to prevent cracking.

Correcting Shape Irregularities

Even with careful planning, shape irregularities can occur during curved wood arch construction. However, these issues can be corrected with a few adjustments. Here’s what you can do:

- Apply moisture: In some cases, the wood may have dried out, resulting in shape irregularities. By applying moisture to the affected area, you can encourage the wood fibers to swell and regain their shape.

- Use steam bending: Steam bending is an effective technique for correcting shape irregularities in curved wood arches. By exposing the wood to steam, you can make it more pliable and reshape it accordingly.

- Employ heat and pressure: Another method to correct shape irregularities is to apply heat and pressure. This can involve using clamps or a form while applying heat through methods like soaking the wood in hot water or using a heat gun.

Preventing And Addressing Drying Or Warping Issues

Drying or warping of the wood is a common challenge that can occur during and after the construction of curved wood arches. To prevent and address these issues, consider the following tips:

- Properly seal and protect the wood: Applying a suitable sealant or finish to the wood can help prevent moisture absorption and minimize the risk of warping or drying.

- Store wood in a controlled environment: Wood should be stored in an area with stable temperature and humidity levels. This helps prevent drastic changes in moisture content, which can lead to warping.

- Use the right construction techniques: Ensure that the arch is constructed with even and balanced forces to minimize strain and potential warping issues.

- Allow for proper acclimation: Before starting the construction, allow the wood to acclimate to the environment in which it will be installed. This allows the wood to adjust to the moisture levels, minimizing potential drying or warping problems.

Remember, troubleshooting common challenges in curved wood arch construction is all about proper planning, selection of suitable materials, and employing the right techniques. By being mindful of potential issues and taking the necessary steps to address them, you can achieve beautifully crafted and durable curved wood arches.

Maintenance And Care For Curved Wood Arches

Wood arches add a timeless and elegant touch to any architectural design. Whether you have a curved wooden arch above your entryway or as a decorative feature in your living space, it’s important to understand how to properly maintain and care for these beautiful structures.

In this section, we will explore some key maintenance tips and discuss the use of protective coatings and sealants to ensure the longevity of your curved wood arches. So let’s dive right in and discover how to keep your wood arches looking their best.

Regular Cleaning And Dusting

Keeping your curved wood arches clean is essential for their long-term durability and visual appeal. Here are a few key points to consider:

- Dusting: Regularly dust the surface of your wood arches using a soft cloth or a feather duster. This will help remove any accumulated dirt or debris that can tarnish the appearance of the wood.

- Gentle cleaning: Occasionally, you may need to give your arches a deeper clean. Use a mild dish soap mixed with warm water to create a gentle cleaning solution. Apply the solution to a soft cloth and gently wipe down the wood surface. Avoid using abrasive cleaners or scrub brushes, as these can damage the wood finish.

- Drying: After cleaning, make sure to thoroughly dry the wood arches to prevent moisture from seeping into the wood and causing damage. Use a clean, dry cloth to gently wipe away any excess moisture.

Protective Coatings And Sealants For Longevity

In addition to regular cleaning, applying protective coatings and sealants is crucial for maintaining the strength and beauty of your curved wood arches. Here are a few important points to consider:

- Natural finishes: Opt for natural finishes, such as tung oil or linseed oil, to protect the wood and enhance its natural beauty. These finishes penetrate the wood, providing protection against moisture and uv damage. Apply the finish according to the manufacturer’s instructions, ensuring even coverage and allowing sufficient drying time between coats.

- Outdoor protection: If your wood arches are exposed to the elements, it is essential to use a weather-resistant protective coating. Look for products that offer uv resistance and protection against water damage. Apply these coatings as per the manufacturer’s guidelines and reapply as needed.

- Regular maintenance: To ensure the longevity of your wood arches, it is important to inspect and maintain the protective coating regularly. Look for signs of wear or damage, such as peeling or fading. If necessary, clean the surface and reapply the protective coating to maintain optimal protection.

By following these maintenance and care tips, you can ensure that your curved wood arches remain a stunning focal point in your space for years to come.

Frequently Asked Questions For How To Make Curved Wood Arches

How Do You Bend Wood For Arches?

To bend wood for arches, you can use steam or heat. Steam bending involves applying moisture and heat to make the wood more malleable, while heat bending requires applying heat using a heat gun or an oven. Both methods require careful planning and technique to achieve the desired curve.

What Types Of Wood Are Best For Making Curved Wood Arches?

The best types of wood for making curved wood arches are those with high flexibility and bending potential, such as ash, oak, cherry, or walnut. These woods have long fibers that allow them to bend without breaking and maintain their strength and structural integrity.

How Long Does It Take To Make A Curved Wood Arch?

The time it takes to make a curved wood arch depends on various factors, including the complexity of the design, the wood type, and the bending method used. On average, the process may take anywhere from a few hours to a few days, considering the preparation, bending, drying, and finishing stages.

Can you install a gooseneck hitch yourself?

you can install a gooseneck hitch yourself, but it requires some mechanical know-how and the right tools. Before starting, ensure you have the appropriate hitch for your vehicle, read the installation instructions thoroughly, and always prioritize safety. If you’re not confident in your abilities, it’s best to seek professional assistance.

How do you bend wood to make an arch?

Bending wood for an arch involves a process called steam bending.

Here’s a basic overview:

a. Choose a suitable type of wood; thinner boards are generally easier to bend.

b. Build or acquire a steam box. This is a sealed container where wood is exposed to steam.

c. Steam the wood for about 1 hour per inch of thickness to make it pliable.

d. After steaming, quickly move the wood to a form or jig that has the desired arch shape. Clamp the wood into place.

e. Allow the wood to cool and dry in the form. Once removed, it should retain the arched shape.

How do you make a wooden arch out of wood?

Making a wooden arch can be achieved in several ways. One method involves cutting segments and joining them together.

Here’s a simple process:

a. Decide on the desired size and radius of your arch.

b. Cut several segments of wood that, when placed side by side, will create your arch’s curve.

c. Smooth the edges of each segment to ensure they fit together seamlessly.

d. Join the segments using wood glue and, if necessary, reinforce with screws or dowels.

e. Sand the joined arch for a smooth finish.

How do you make a perfect wood arch?

To make a perfect wood arch, precision in measurement, cutting, and joining is key. Use templates or jigs for consistent curves. CAD software or a compass can help in plotting the exact curve. Always measure twice (or more) and cut once. Additionally, using high-quality, straight-grained wood can make the bending or joining process smoother.

Conclusion

Crafting curved wood arches adds a touch of elegance and sophistication to any woodworking project. The knowledge and skills required to create these beautifully curved elements may seem intimidating at first, but with the right guidance and practice, anyone can master the art of making curved wood arches.

By understanding the principles of wood bending and employing the appropriate techniques, you can create stunning arches that enhance the aesthetics and functionality of your furniture or architectural design. Experimenting with different types of wood and exploring various techniques, such as steam bending or laminating, opens up a world of possibilities for creating unique and eye-catching curved wood arches.

So, whether you’re a seasoned woodworker or a novice enthusiast, don’t be afraid to embrace the challenge of crafting curved wood arches – the results are sure to be worth the effort. Let your creativity take flight and enjoy the satisfaction of bringing beautiful, curved wood arches to life.